Refrigeration Cold Room Freezer Cold Storage Walk in Cooler for Frozen Meat

Basic Info.

| Model NO. | OnlyKem Cold Storage |

| Warranty | 1-2 Years |

| Certification | ISO, CE |

| Condition | New |

| Evaporator | Air Cooled(Ceiling Mounted, Floor Mounted) |

| Cold Storage Usage | Meat/Seafood/Vegetables/Fruit |

| Condenser Type | Fnv / Fnh (Air Cooled, Water Cooled, Evaporative) |

| Voltage | 220V, 380V, 420V, 440V(All Types Are Available) |

| Key Selling Points | Easy to Operate |

| Service Door | 36 X 81" Metal Plugin Service Dpoor |

| Color | According to Customer Requirement, Default Is Milk |

| Steel Material | Stainless Steel, Color Steel, Embossed Aluminum |

| Floor of Cold Storage | PU Penal/Concrete with XPS / Checker Plate |

| The Thickness of PU Panel | 50 75 100 120 150 200mm Are Optional |

| Refrigeration System | New Generation of Smart Cooling System |

| Cold Storage Doors | Hinged / Sliding / Swing / Lifting Doors |

| Cold Storage Panel | PU Foam Core Sandwich Panel |

| Transport Package | Plywood Box for Cold Storage |

| Specification | Customized |

| Trademark | OnlyKem |

| Origin | China |

| Production Capacity | 1000 Sets Per Month |

Product Description

Refrigeration Cold Room Freezer Cold Storage Walk in Cooler for Frozen Meat

Cold storage has a wide range of application such as fruit, vegetable, fish, meat preservation. It proves to be thebest food preservation solution with its fast freezing time and great thermal installation performance. It is a reliableand energy-efficient machine that is guaranteed with a long service life and low operating and maintenance costs.Feature:1. Good performance: the coldest temperature can be as low as -20°C.2. The production is fast and the construction period is short.3. Customization: the size of the refrigeration warehouse is determined according to customer needs.

| Different Types of Cold Storage Parameters | |||

| cooler room | -5~5 ºC | For fruits , vegetables , milk , cheese etc | 75mm,100mm panel thickness |

| freezer room | -18~-25 ºC | For frozen meat , fish , seafood , ice cream etc | 120mm,150mm panel thickness |

| blast room | -30~-40 ºC | For fresh fish , meat ,fast freezer | 150mm,180mm,200mm panel thickness |

Insulation System

PUR/PIR Panel| Thickness | 75mm 100mm 120mm 150mm 200mm |

| Width | Standard: 950mmCustomization Available |

| Length | Maximum 10m without connection |

| PU Parameters | Density ≥ 42kg/m³Flame Retardent Time ≤ 5sHook Distance = 900mm |

| Plate | Color Steel |

| Stainless Steel | |

| BaoSteel | |

| Embossed Aluminium | |

| Cold Storage Door1.Perfect sealing2.Reliable, safe and easy to operate3.Cold Room Door Series: hinged door,sliding door,swing door,replaced door4.Replaced Door: Whether you want to replace the original door or open a new door of the old cold room. | |

Smart Packaged Unit•Compressor HP: 2-15hp•Working Temp.:+5~-30ºC•Compressor Type: Scroll / Rotary•Independent developed smart CDU(Condensing Unit) controller •Advanced fuzzy controlled EXV module •Intelligent hot-gas defrost on demand •Condenser fan-speed controls•Self-diagnosis function Intelligent alarm system | Condensing Unit•Compressor Optional:1-Hermetic Scroll2-Semi-hermetic or Screw•Condenser:Air cooled or Water cooled•Frame:can be stell shell with spray painting or open type on stell frame•Refrigerant:R404a |

| Unit Cooler* Collared fan outlet for wide air throw* SS ceiling mounting clamps for easy installation* Double drip tray* Al Mg powder coated, GI powder coated & SS 304 casing for rust free operation* Bullet expansion on tubes* Cooling capacity ranging from 1.2 kW to 60 kW* Fin spacing available from 4.5 mm to 12mm | |

Customer Case

Packaging & Shipping

The protective packaging of the Smart Packaged Unit:1. Wooden box: fix the compressor and fan to prevent shaking2. Bottom support: easy to load and unload to prevent packaging damageThe protective packaging of the PU Panel:1, film packaging to prevent moisture, rust and transportation scratches2. Four-corner cardboard protection to prevent impact3, neatly placed, avoid shaking

Company Profile

FAQ

Q:How long is the lead time?

A:Usually for units we need 35 days to produce. If it is a special voltage of 60hz, the production time needs to be extended by 5-10 days. Panels and other things usually we need 7-20 days depends on amount

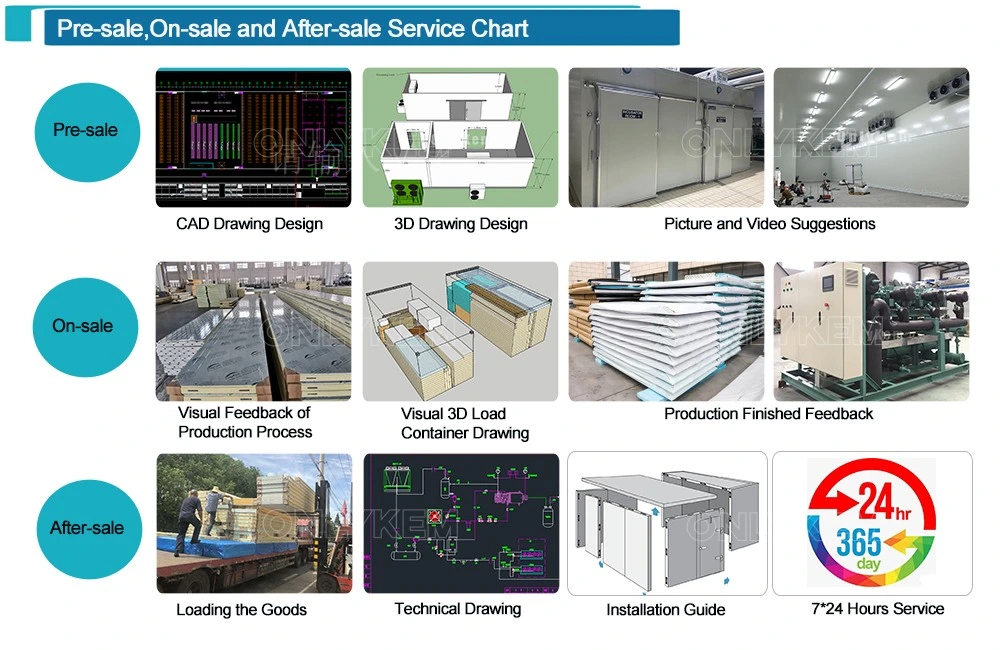

Q:What kind of technical support can you provide?

A:Both our sales and engineers can provide 24 hours online support. Panels are supplied with installation drawings. Installation manuals and electrical diagrams are included with the cooling system. Accessories support is available for all of our products

Q:Can you send an engineer to the site to install?

A:At present, due to the epidemic, the cost of our engineers going abroad is too high. Returning from abroad requires up to 14 days of quarantine. We recommend that it is more cost effective to find a refrigeration engineer locally. We can provide full online technical support

Q: Do you accept customization?

A: Since we are a factory, we accept customer's customization. If you need to use your brand, please provide the AI/PSD source file of the brand logo

Q: Can you provide samples?

A: Hello, most of our products can provide samples. Sample fee and shipping fee will be paid by customer. Panel samples can be provided free of charge. Shipping is paid by the customer.